new power supplyRevox B77

1.177.313 new developments

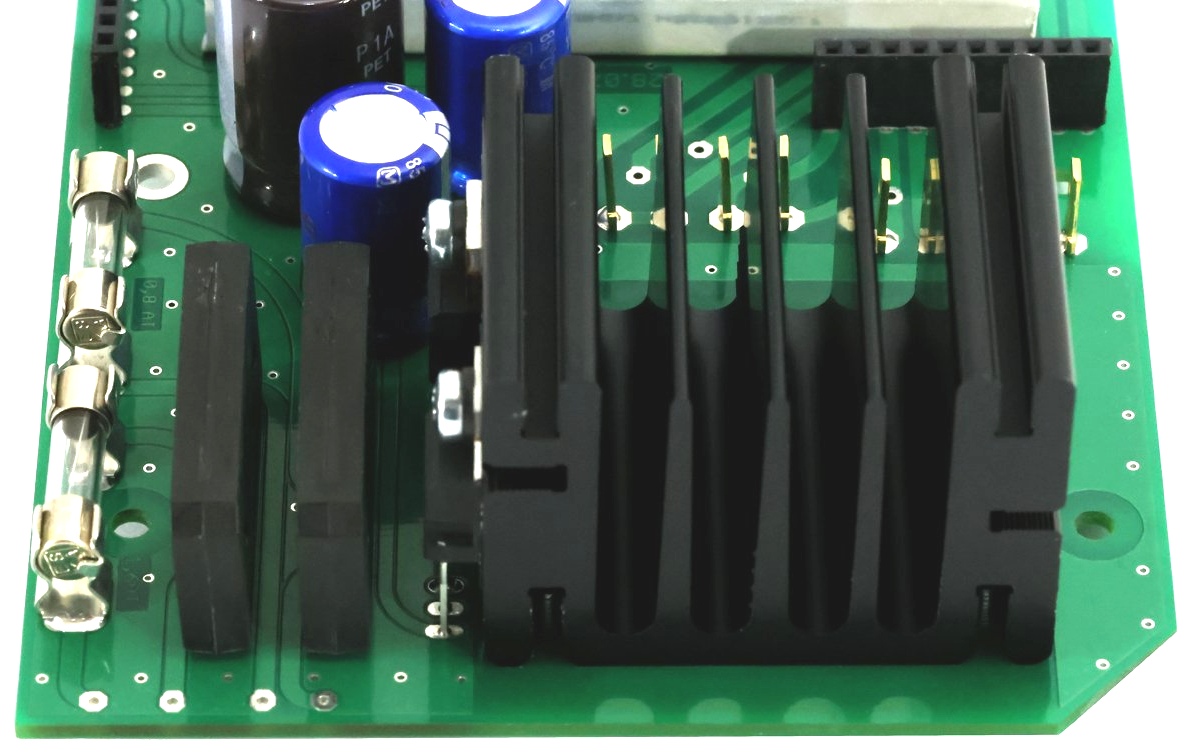

Here comes the brand new power supply board for all Revox B77 tape recorders.

The new circuit board has been designed with audiophile standards in mind. We've added additional suppression capacitors to the AC input voltages of the power supply board. The rectifiers have four additional parallel capacitors, and the conductor tracks are extra wide, measuring 70 µm thick! Additional filters include LC elements, blocking capacitors, and buffer capacitors.

The biggest challenge is certainly installing the new circuit board. The machine requires extensive disassembly, and the connections coming from the transformer have to be soldered.

the technology

two separate regulators

Two LM317

Here, too, we've dispensed with exotic voltage regulators. We prefer to use the well-known LM 317 regulators. The regulators are mounted on a proper heat sink. The heat sink is positioned so that the air can flow as freely as possible due to the thermal conductivity and dissipate as much heat as possible! The rectifiers are also positioned so that the Air can flow past particularly well.

Furthermore, the rectifiers are very large, oversized and no longer covered by the too small and too hot cooling plate!

Power loss

The overall power loss has remained the same. It's just that the power loss is split between two voltage regulators. More important, however, is the separate 21 V power supply for the audio boards and the speed control, which also now supplies the capstan control or speed control with a separate 21 V from the second transformer winding.

Filter

2 LC elements

The coils, together with the charging capacitors, not only form an LC low-pass filter with a cutoff frequency starting at approximately 300 Hz, but also effectively limit the charging current peaks, effectively suppressing and preventing interference spikes and transients. All of this stabilizes the operating voltages and reduces residual ripple.

Ten capacitors

We use 10 additional capacitors to stabilize the rectification and AC input voltages. We're not simply copying this; others can do that – not us at Premium-Hifi! After all, the power supply is the foundation and should be well-designed, utilizing all of today's possibilities and current knowledge!

Premium power supply

The control voltage is completely separated from the audio voltage. Not only do we have to build the voltage regulator twice, but the voltage itself now comes from the transformer winding that supplies the logic circuit, rather than the transformer winding that powers the audio section! Does this help?

It would be a shame if we hadn't used this option!

Power strips

for through-hole contacts

There isn't much choice!

Since we also want to offer our circuit boards individually, we need to be compatible with existing circuit boards and peripherals. Male and female connectors with 5.00 mm pitch are rarely available anymore, rather than 5.08 mm. The difference might be acceptable for smaller connectors with 3 or 4 contacts, but with 15 contacts like the one used in the drive controller, it's no longer possible!

Since we also want to offer our circuit boards individually, we need to be compatible with existing circuit boards and peripherals. Male and female connectors with 5.00 mm pitch are rarely available anymore, rather than 5.08 mm. The difference might be acceptable for smaller connectors with 3 or 4 contacts, but with 15 contacts like the one used in the drive controller, it's no longer possible!

the layout

The conductor tracks

The printed circuit boards are particularly wide and round. The printed circuit boards for the motors are also all double-sided. We cannot change the positions of the plugs, sockets, and fuses; these positions are determined by the tape machine and are rigid specifications that we, too, must adhere to. Even worse is the availability of the special socket strips with 5.00 mm pitch and the socket strip with through-hole contacts for the speed control.

Shielding

There is only shielding around the low voltage.

As with the new Tape drive control, the cables around the motors are not shielded. The mounting of the circuit board is also predefined and cannot be changed.

Two tin bridges ensure compatibility with the MK I or MK II versions of the Revox B77. Thus, the power supply fits all Revox B77s.

the installation

Housing

Ventricular fibrillation caused by an electric shock can be fatal even after three months! Always seek medical attention after an electric shock!

Tape drive control

To remove the drive control of the Revox B77, the screw on the drive control's heatsink must be loosened and all connectors on the drive control must be removed. J5 on the power supply board; the front 15-pin connector can also be removed.

Now pull the circuit board away to the outer edge.

Remove transformer unit

Soldering experience is required!

Unplug

Before loosening the four transformer screws, you should remove all pluggable connections from the power supply board (11 flat connectors to the motors, 2 flat connectors coming from the speedometer, and connectors J1, J4, and J5). Even though the color-coding is described in our manual, it's never a bad idea to take a few quick photos with your phone!

Lining

You should create a work surface behind the device using books, boxes, or cartons approximately as high as the transformer. After unscrewing the transformer, you can place the transformer on the work surface, unscrew the power supply board, and desolder the wires. The exact height isn't important. The transformer unit shouldn't pull on the cable when resting on the work surface.

Caution! Do not drop the unit, as this could cause the transformer to pull on the cable!

Put down the transformer

The transformer should be removed and reinstalled as a complete unit, including the connector panel and power supply board. Now you have easy access to the power supply board and can perform all the necessary work easily and conveniently. And while you're at it, you should also replace the mains interference suppression capacitor behind the connection panel.

Unscrew the power supply

Once the circuit board is unscrewed, you can desolder the soldered wires coming from the transformer. Again, taking a few photos with your smartphone will make reassembly easier. The positions of the wires on the new circuit board have not changed. This is also described in the instructions!

manageable effort

The effort is relatively high. However, it's all quite doable. Using the procedure described here, it can be done quickly by hand. We always include the noise suppression capacitor connected to the mains voltage. We consider replacing the noise suppressor to be important! Anyone who enjoys tinkering and knows a bit of soldering will be able to handle it. The big advantage of the new power supply is the complete separation of the voltages for the audio and control circuits!

new Power supply 1.177.318

for all Revox B77 you can find in our shop