pressure roller

It was a long and arduous journey until we were able to offer you the pressure rollers in the current quality. Not only the materials used for the rubber (we have never used polyurethane) and the bearing, but also the manufacturing and the necessary steps had to be found and developed first.

The final step is to grind the rubber to a round shape and ream the sintered bushing. Before this, the edges of the rubber are chamfered at a 45° angle.

All our pressure rollers are supplied with the appropriate sintered bearing oil and are therefore maintenance-free. We can also offer you suitable accessories for the pressure rollers such as sintered bearing oil, Teflon sliding washers, circlips and copper washers.

Revox A77

with 11 mm axle length

Installation in A77

Installation isn't quite so easy; you have limited space, and the lower Teflon sliding disc tends to slip and fall into the device. Then it's a matter of searching, finding, and starting all over again :-)

Revox B77

with 9 mm axle length

Pressure roller B77

also suitable for Revox A700, PR99 MKI, MKII, MKIII, C270, C274 and Studer A67, B67, A807, A810.

We use only genuine rubber. After vulcanization and pressing the sintered bearing into the brass bushing, the round grinding and 45° chamfer are applied. This is the only way we can meet Studer and Revox specifications! All new orders will receive the new company name, abbreviated to "Premium-Hifi."

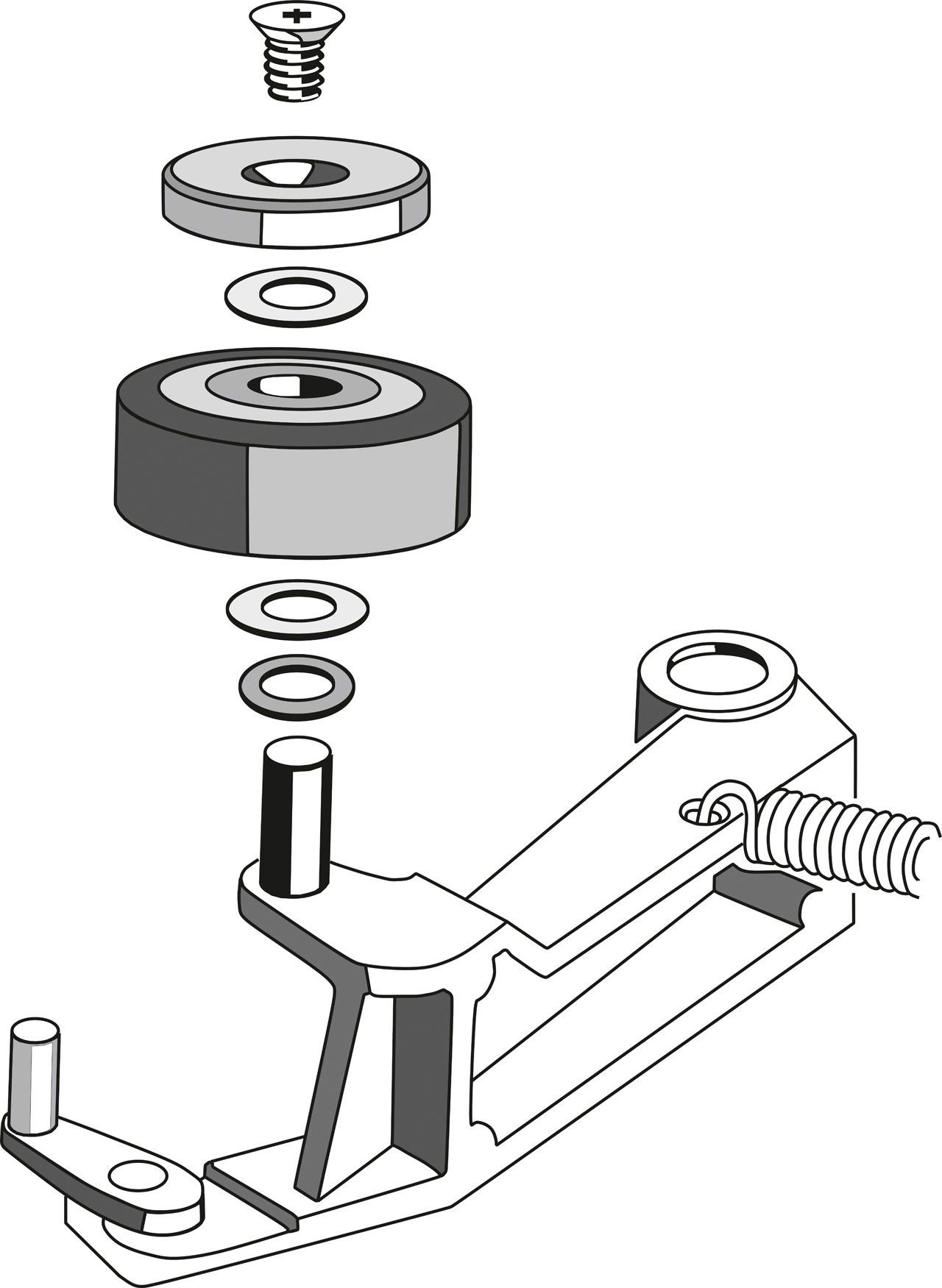

Installation in B77 / PR99

First, the copper washer goes on the axle, then a Teflon washer, then the pressure roller, another Teflon washer and only then the cover!

We've seen some of the most amazing things: sometimes all the discs are at the bottom, sometimes all at the top, sometimes no discs at all, and sometimes with too many discs, which causes the roller to jam! Often, the copper disc is missing, and then the pressure roller has too much play on the axle, and the tape can no longer be guided properly!

Here too we offer suitable accessories such as the stainless steel countersunk screw M3 x 8 mm the Teflon washers (sliding washers) 5 x 10 x 0.25 Copper disc 5 x 8 x 0.15 and so on.

Revox A700

Study A807

Installation in Studer A807

Like the Revox A700, Studer A67, and B67, the Studer A807 doesn't use any discs. It couldn't be easier. Loosen the screw, remove the cover, replace the pressure roller with the premium hi-fi quality pressure roller, and reassemble!

The exploded drawings are taken from the original service manuals of the respective devices and have been redrawn by us.

Study A810

Installation Studer A810

Unscrew the lid, replace the pressure roller, screw the lid back on – that's it! What was expected of amateurs was simply left out of the discs for the professionals!

Our pressure rollers meet all the requirements for studio applications. Synchronization and durability are particularly important here!

Revox B710, Studer A710

Danger!

There are differences in the diameter of the pinch rollers on the Revox B710 and Studer A710 cassette decks!

The first version has two different sizes of pressure rollers.

The left pressure roller has a diameter of 8.0 mm and the right pressure roller has a diameter of 8.6 mm.

The second version has two pressure rollers, each with a diameter of 13.0 mm.

Here too, our rubberized pressure rollers have a sintered bronze bearing and are ground round and the bearing bush is reamed in the final operation.

Size difference

If the pressure rollers are placed next to each other, the size difference is immediately apparent.

Condition and without comparison the difference is difficult to see.

Andruckrolle 8,6 mm

The right pinch roller could also accommodate the 8.0 mm pinch roller. This would not change the speed. The speed is determined solely by the circumference and rotational speed of the capstan shaft, but installing the 8.0 mm pinch roller would be completely wrong!

Montage

First, the spacer washer, then a Teflon washer, the pressure roller, another Teflon washer and finally the shaft retaining ring are fitted onto the axle.

There is no groove for the shaft retaining ring. The shaft retaining ring is pushed onto the axle until the pressure roller has minimal play (0.1 mm).

Revox B710, Revox B215,

Studer A721

Andruckrolle 13 mm

Left pressure roller of the Revox B710 with 13 mm pressure roller.

In relation to the capstan shaft, the 13 mm reel is clearly visible.

pressure rollers

in our shop

Here you will find the precision pressure rollers for many

Studer and Revox cassette decks